Ram Truck: Holden's Hero

Reading by the warm fire, accompanied by a cup of tea, is a classic winter picture. However, for Ram Heavy Duty, who wrote his own book and prefers octane to Earl Grey, the perfect snow day is completely different. Cold is something to be embraced, not something to be hidden. This is an opportunity to improve Ram’s sense of purpose, and it now has first-class ratings in terms of fuel economy and traction.

We are going well north to Houghton, Michigan, where Ram takes merciless winter weather and literally “plows” through it. A series of intense vehicle tests, on a real world proving ground, that would swallow lesser automobiles. The conditions Ram endured recently in Houghton County show how surviving sub-zero weather in Michigan will later be duplicated on an assembly line and sold to the world.

Test #1 – Slush Packing

Test #2 – Snow Ingestion

Test # 3 – Plow Power

Points of Interest

Test #1 – Slush Packing

Driving through a wintry mix is difficult enough but how about parking afterwards? When everything collected underneath; the water, snow and slush combos become bricks of ice? It takes over the components and imprisons the entire undercarriage of the truck. Fuel lines, brakes, suspension components, the oil pan – all of these vital parts become grasped in winter’s cold hands.

Ram engineers drive the trucks through 12-inch-deep slush, then pull into special a refrigeration facility. They set the dial to minus 20, then returned the next morning to inspect the results. Did all the components underneath still meet their specifications?

“When it’s minus 20 outside and I walk up to my Ram Truck on a morning of a Michigan winter, I have a sense of self-reliance and assurance that my truck will start, warm up quickly and run well,” said Mike Cairns, Director of Ram Truck Engineering.

The diesel exhaust fluid tank and corresponding lines, made of materials to combat frost held up. A heating system keeping a portion of DEF above freezing allowed the engine to start. And because of the strategic location of vent lines, ice was unable to block them. This gave full function of the truck’s transmission, transfer case and windshield wipers.

Test #2 – Snow Ingestion

This one is just plain nasty. When seeing the designs for this test and the intent, I get goosebumps. Ram engineers literally force the trucks to breathe in massive amounts of snow, while running them for hours at a time.

Works like this: The lead truck pulls a chain link, grid device called a “drag.” When paraded through the snow it, kicks up whirlwinds of winter rage for the trucks following to drive through. This pushes the Ram Active Air intake system, the first of its kind in the automotive industry.

When vehicles encounter blowing snow, air filters can become clogged as the vehicle breathes. The resulting effects compromise the intake system and subtract performance. Yet, Ram trucks behind the “drag” breathed wonderfully, thanks to an under-hood inlet. This air path is protected from invading snow, ice and slush. The Ram Active Air intake system works intelligently too, switching “breathing patterns” depending on the driving conditions.

This helps the Ram lend its balance of fuel economy and power, be it a Michigan winter or Texas summer.

Test # 3 – Plow Power

80 percent of commercial and private plow trucks are 3⁄4-ton or greater and as Ram reaches that market, documenting the results of plow tests are vital. Ram engineers plow more than 10,000 tons of snow each winter as part of their ongoing research. Plow truck operators will take multiple passes in a small area, pushing forward and then reversing out. This is common in parking lots.

Think of how that constant shifting, from reverse to drive, puts increased strain on the transmission. Ram engineers use plow tests to see how the transmission holds up under pressure. One measure of merit for a truck is how efficiently and seamlessly it gets torque to the wheels. Plow testing is a measure of the same, except with a massive pile of snow now creating resistance.

Sometimes, we encounter that here in Michigan. Resistance. There are many negative stories about Detroit and the state in which she rests. However, what these tests show, more so than a capable truck, is how we as the American Automotive Industry face resistance.

With persistence.

And we take that persistence, bottle it up and mass-produce it. That creates jobs here and satisfied customers all across the globe.

Welcome to a typical day in Michigan . . . cold yet?

https://www.youtube.com/watch?v=G6Z2jL85f3Q

Special Thanks: Nick Cappa, Ram Truck Media Relations ([email protected])Photos: Fiat Chrysler Automobiles

Points of Interest

Ram 2500 and 3500 are available with a Snow Chief Package, which includes:

Upgraded cooling system

Higher-amp alternator

Anti-spin differential

More robust front suspension

Plow lighting interface eliminates the need for a lighting harness and enables plow lights to override the headlights upon plow installation

Transfer case skid plates

Auxiliary switches to operate the plow

Clearance lamps

OWL 18′′ tires

All Chassis Cab trucks come standard with heavy duty cooling, auxiliary switches, limited slip rear axle and clearance lamps. For a full list of options, availability and related pricing, visit with a Ram Trucks Certified Sales Consultant.

Ram engineering tested trucks with new and more “experienced” plows. V-shaped and straight plow combinations were used to cover a wide range of equipment.

Moving into the 2015 model year, Ram holds:

Best-in-class fuel economy with exclusive EcoDiesel – 29 mpg with Ram 1500

Best-in-class towing capability – 30,000 pounds with Ram 3500

Best-in-class payload – 7,390 pounds with Ram 3500

Best-in-class torque – 865 lb.-ft. with Ram 3500 equipped with Cummins

Ram Engineering conducted a large number of laboratory tests at the company's technology center in Michigan, and completed vehicle tests at the company's two main test sites in Arizona and Michigan. The goal is to ensure that all Ram trucks are fully capable of withstanding the harshest environments. In addition to Holden, Ram also traveled to Bemidji, Minnesota for a similar cold weather test.

-

Latest

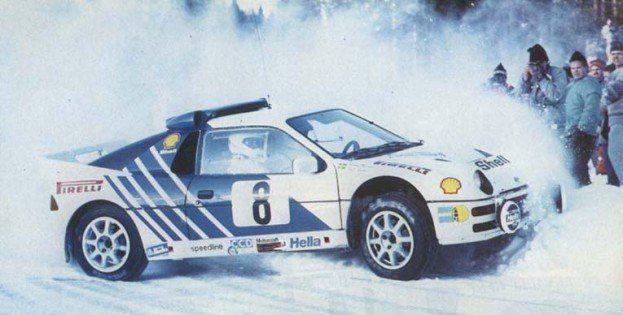

Group B Friday: Ford RS200 is late

Group B Friday: Ford RS200 is lateFord's RS200 is in action.At the beginning of the Group B era, when Audi’s Quattro and Lancia’s 037 were the only serious competitors, Ford was developing a new rally contender to replace the successf...

-

Next

2015 Modern Genesis Review

2015 Modern Genesis Review2015 Hyundai GenesisProsInterior QualityPower of 5.0Amount of FeaturesConsNo 5.0 AWDLane Departure SystemNot as Sporty as Competitors91Hyundai has been working diligently these past few years to alter...

Popular Articles

- The Canadian government invests in the first Canadian-made electric car

- Stellantis strengthens electrification

- 2022 Ford Maverick debuts

- The Canadian government requires 100% of Canadian car and bus sales to achieve zero emissions by 2035

- Extend electric car rebates to businesses and non-profit organizations BC

- New general manager of ADESA offices in the U.S. and Canada